The right flow

for Your intralogistics!

EtE®flow is the missing element in your intralogistics. By becoming your partner, we will create a fully automated and optimal system of logistics processes for your company.

-

Exchanging pallets without stopping

the robot’s operation -

Mobility and Space

saving -

Remote access adn quick installation

and configuration -

Training for operators and

maintenance departments

Benefits of Using EtE®flow PalletCell

- Improved efficiency of the manufacturing process

- Flexibility to adjust quickly to market needs and orders

- Saving on transportation costs

- Continuous operation minimizing the impact of staff absence

- Enhanced safety, reducing the risk of accidents and injuries

- Cost reduction through quick installation

- Increased performance while lowering the costs to yield higher profits

EtE®flow products

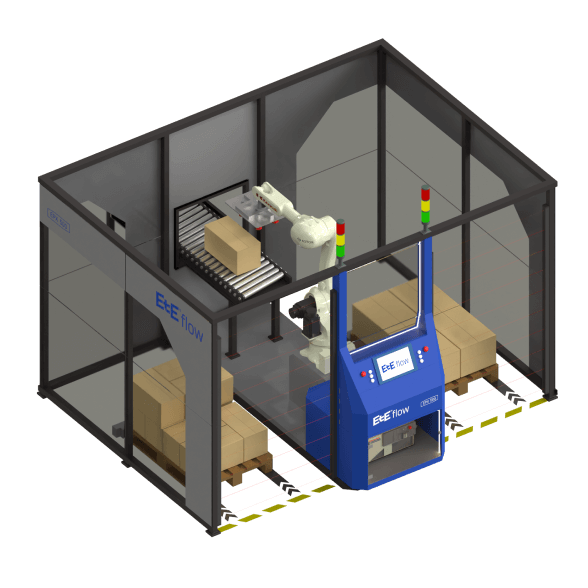

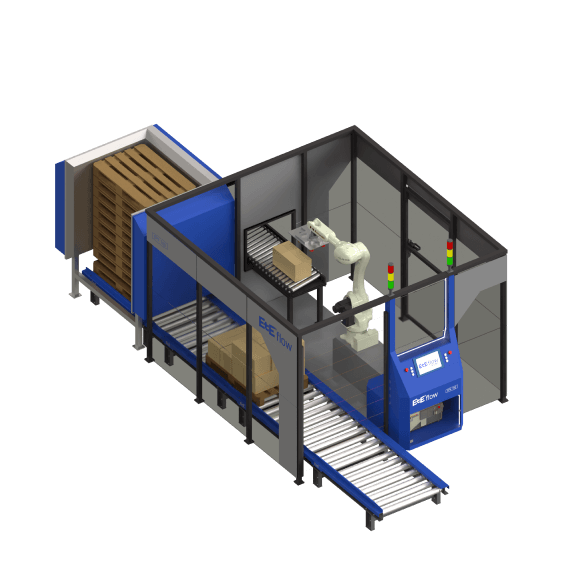

EtE®flow Pallet Cell 500

With pallet conveyors to allow pick-up and loading of pallets without interfering with the working space of the robot.

- Allows palletization of up to 2 full pallets without an operator present, possibility to extend conveyors and increase the number of full pallets

- Increased productivity – no need to slow down the robot during pallet changeover

- Allows pallets to be picked up and loaded easily

with a mobile robot

or forklift - Allows further expansion of the system, passing the pallet

to the next stage

-

Changing the palette without stopping the robot's operation

-

Mobility and

Space saving -

Remote access adn quick installation and configuration

-

Training for

operators and maintenance departments

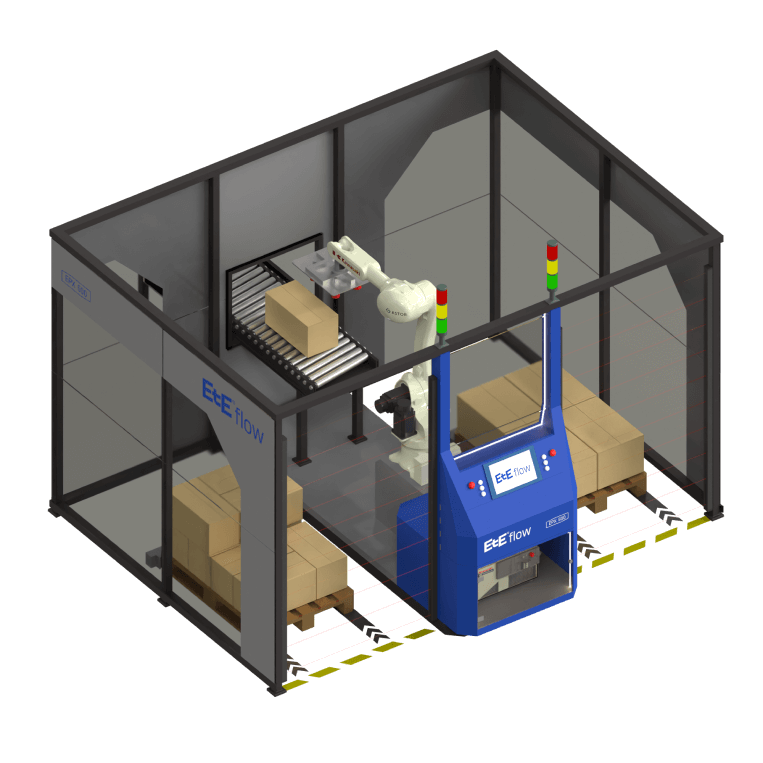

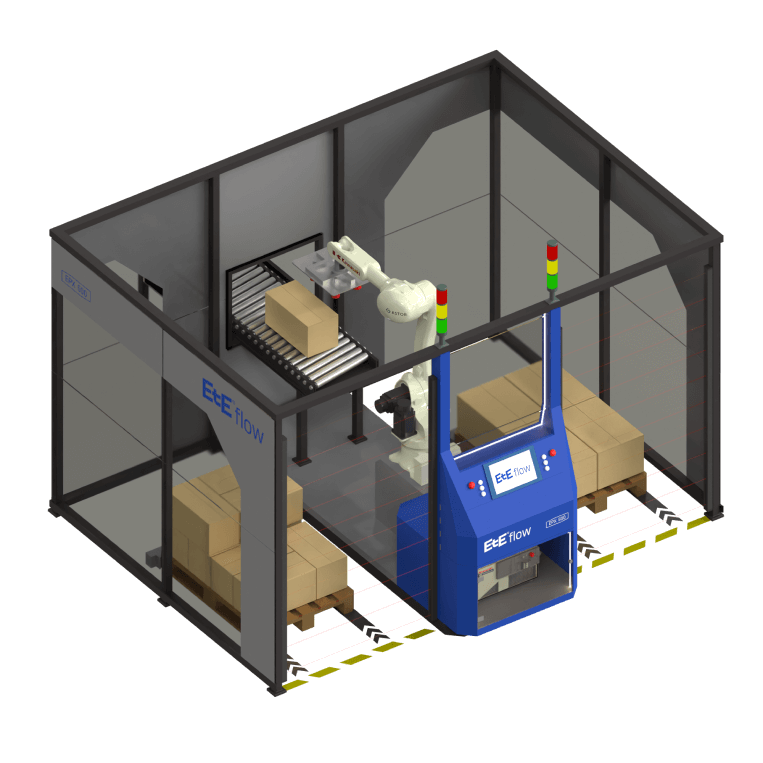

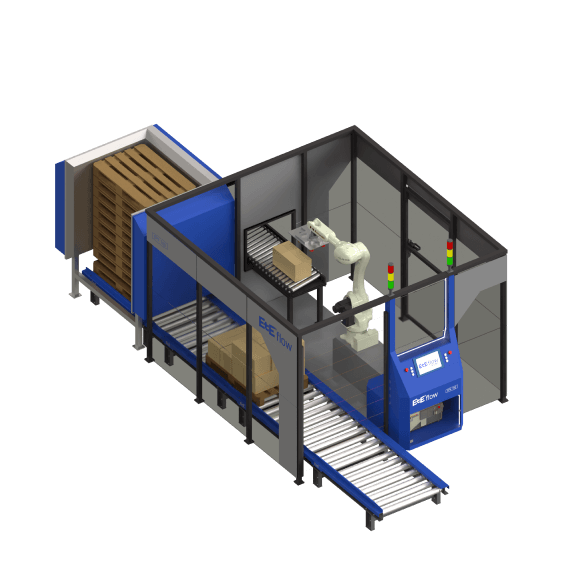

EtE®flow Pallet Cell 600

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE®flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

- Allows palletizing up to 2 full pallets without operator presence.

- Possibility to extend conveyors and increase the number of full pallets.

- Increases efficiency – there is no need to free up the robot during pallet exchange.

- Allows for easy pallet pickup and loading by a mobile robot or forklift.

- Enables further expansion of the system, transferring the pallet to the next stage.

-

Higher productivity, palletizing up to

2 full pallets -

Mobility and

Space saving -

Remote access adn quick installation and configuration

-

Training for

operators and maintenance departments

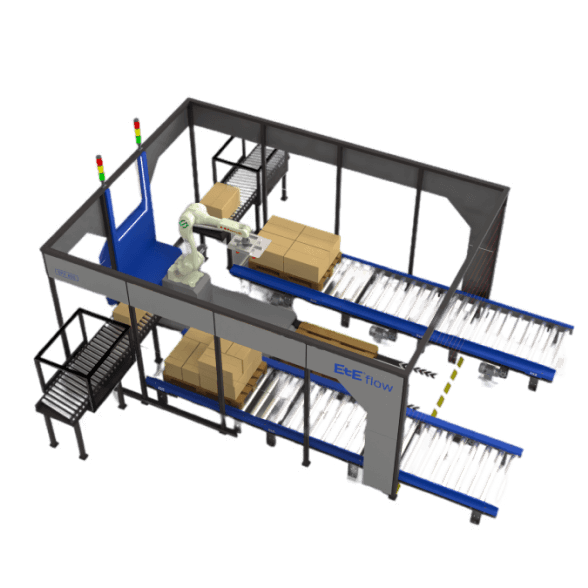

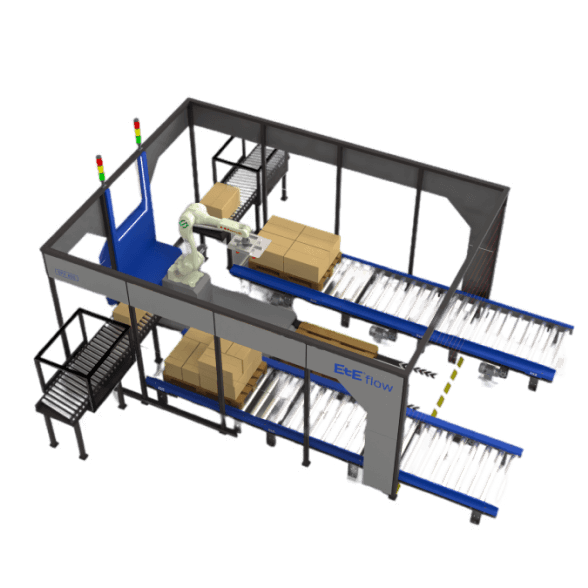

EtE®flow Pallet Cell 700

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE® flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

- Allows for the palletization of 3 full pallets without operator intervention.

- Possibility to extend conveyors and increase the number of full pallets.

- Increases efficiency – no need to free up the robot during pallet exchange.

- Continuous palletization.

- No need to exchange a full pallet for an empty one.

- Allows for the continuation of the palletizing process without interruptions, which also enhances efficiency moving the pallet to the next stage.

- Space optimization.

- The pallet warehouse occupies little space and allows for the storage of pallets, which is especially important in the case of small production halls.

-

Higher productivity, palletizing up to

3 full pallets -

Space optimization, mobility

-

Remote access adn quick installation and configuration

-

Training for

operators and maintenance departments

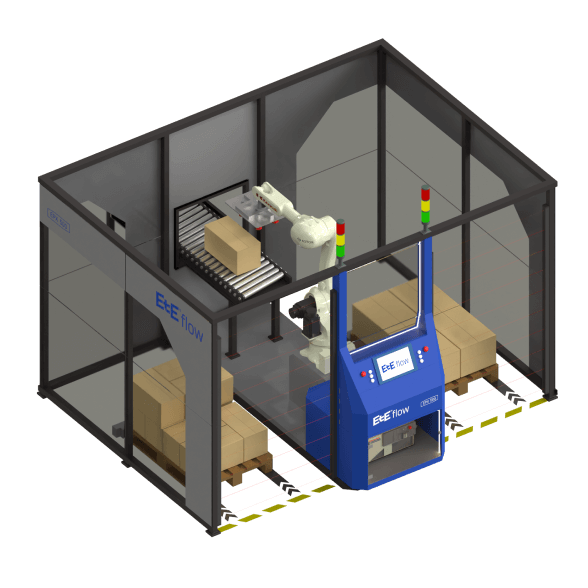

EtE®flow Pallet Cell 800

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE® flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

- Enables independent palletization of two different products.

- Each product has a separate set of conveyors and an increase in the number of full pallets.

- Increases efficiency – no need to free up during pallet exchange.

- Allows for easy pallet pickup and loading by a mobile robot or forklift, moving the pallet to the next stage.

-

Palletizing two different products independently.

-

Higher productivity, palletizing up to

2 full pallets -

Remote access adn quick installation and configuration

-

Training for

operators and maintenance departments

Changing the palette without stopping the robot's operation

Mobility and

Space saving

Remote access adn quick installation and configuration

Training for

operators and maintenance departments

- Allows palletization of up to 2 full pallets without an operator present, possibility to extend conveyors and increase the number of full pallets

- Increased productivity – no need to slow down the robot during pallet changeover

- Allows pallets to be picked up and loaded easily

with a mobile robot

or forklift - Allows further expansion of the system, passing the pallet

to the next stage

Higher productivity, palletizing up to

2 full pallets

Mobility and

Space saving

Remote access adn quick installation and configuration

Training for

operators and maintenance departments

- Allows palletizing up to 2 full pallets without operator presence.

- Possibility to extend conveyors and increase the number of full pallets.

- Increases efficiency – there is no need to free up the robot during pallet exchange.

- Allows for easy pallet pickup and loading by a mobile robot or forklift.

- Enables further expansion of the system, transferring the pallet to the next stage.

Higher productivity, palletizing up to

3 full pallets

Space optimization, mobility

Remote access adn quick installation and configuration

Training for

operators and maintenance departments

- Allows for the palletization of 3 full pallets without operator intervention.

- Possibility to extend conveyors and increase the number of full pallets.

- Increases efficiency – no need to free up the robot during pallet exchange.

- Continuous palletization.

- No need to exchange a full pallet for an empty one.

- Allows for the continuation of the palletizing process without interruptions, which also enhances efficiency moving the pallet to the next stage.

- Space optimization.

- The pallet warehouse occupies little space and allows for the storage of pallets, which is especially important in the case of small production halls.

Palletizing two different products independently.

Higher productivity, palletizing up to

2 full pallets

Remote access adn quick installation and configuration

Training for

operators and maintenance departments

- Enables independent palletization of two different products.

- Each product has a separate set of conveyors and an increase in the number of full pallets.

- Increases efficiency – no need to free up during pallet exchange.

- Allows for easy pallet pickup and loading by a mobile robot or forklift, moving the pallet to the next stage.

EtE®flow Pallet Cell 500

With pallet conveyors to allow pick-up and loading of pallets without interfering with the working space of the robot.

Goals for palletizing EtE®flow

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE®flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

Goals for palletizing EtE®flow

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE® flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

Goals for palletizing EtE®flow

A simple solution that increases the efficiency of the palletizing process with an advanced safety system for operation between the robot and the operator.

Our solutions are flexible, which allows for the expansion of the EtE® flow palletizing system with additional elements at a later time, such as roller conveyors, roller-chain crossings, or an automatic pallet magazine.

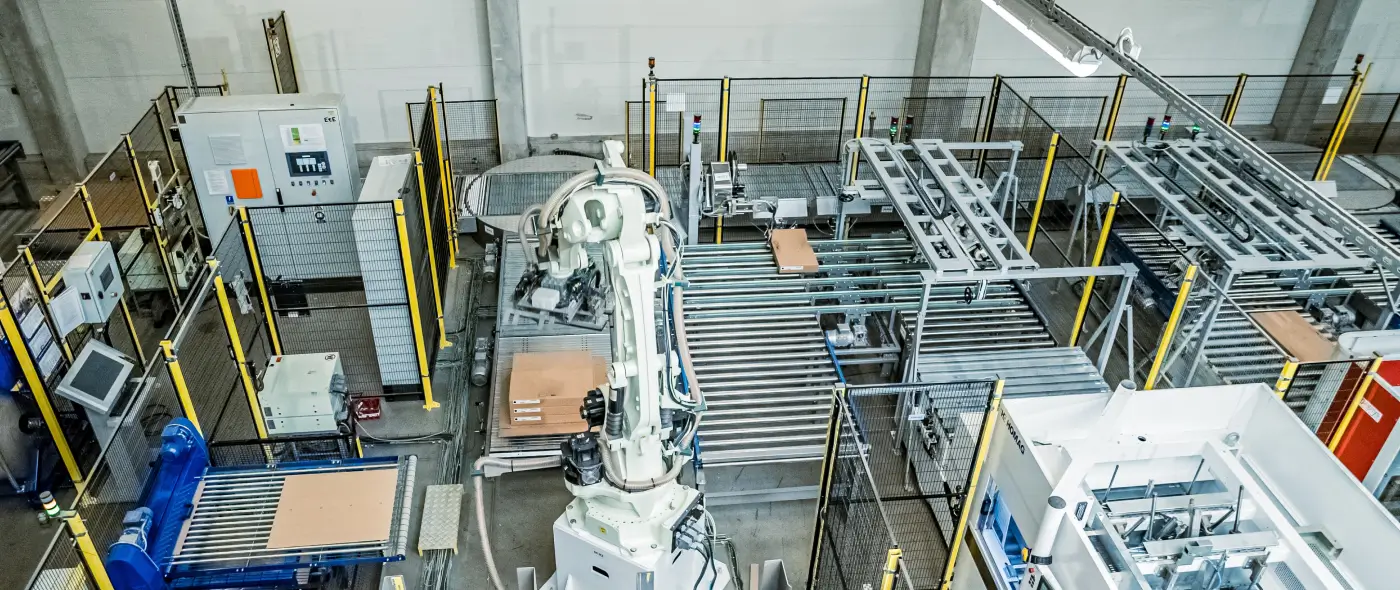

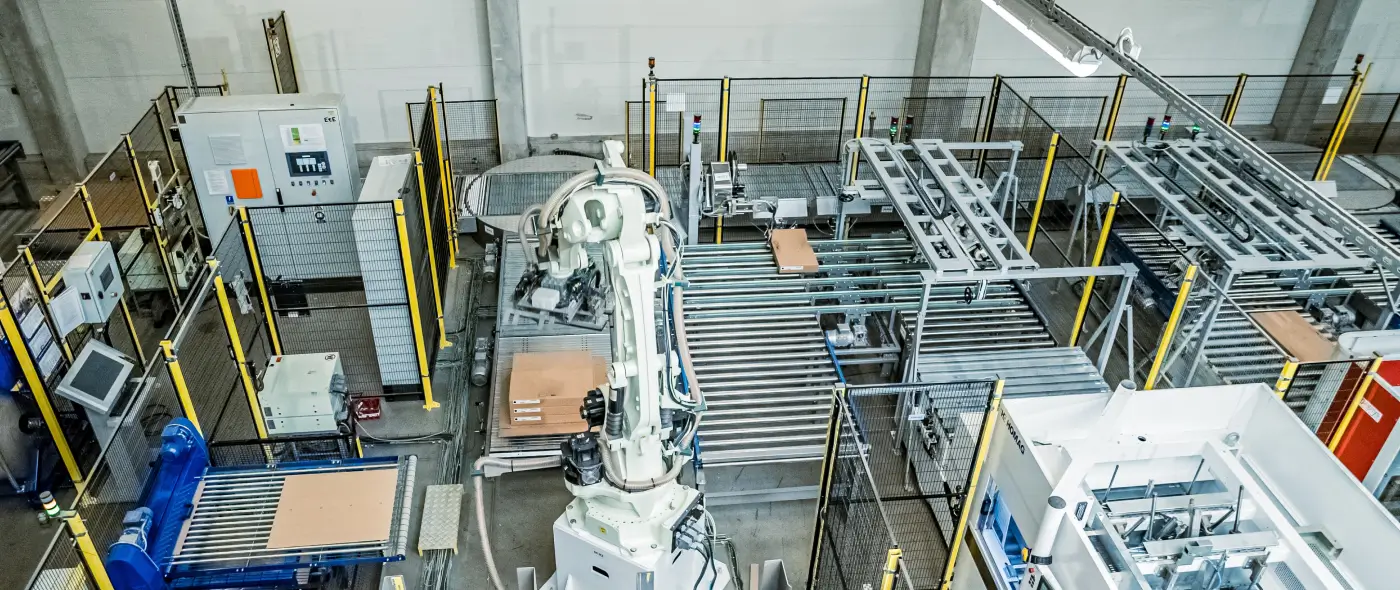

Referencje z realizacji

System paletyzacji z miksowaniem kartonów to nowoczesne rozwiązanie, które automatyzuje proces układania różnych produktów na paletach. Dzięki inteligentnym algorytmom, system optymalizuje przestrzeń, poprawia wydajność i przyspiesza realizację zamówień, co zmniejsza czas i koszty operacyjne. Idealnie sprawdza się w branżach wymagających elastyczności, centrach dystrybucyjnych czy w e-commerce.

System automatycznego transportu palet z wyrobami gotowymi pozwala na obsługę efektu pracy kilku linii produkcyjnych. Składa się z trzech linii transportujących i weryfikujących poprawność palet dostarczonych z produkcji. W branży FMCG transport produktów gotowych odbywa się na paletach EUR oraz DHP. Co ważne, system został tak zaprojektowany, że zapewnia pełne śledzenie produktów w procesie transportu.

Logistyka produkcji i efektywny transport wewnątrzzakładowy montażu krzeseł w firmie Flokk

Wszystkie założenia w tym projekcie, które były na początku, czyli skrócenie czasu tag timu, zminimalizowanie czynności, które są tą wartością niedodaną. Zwiększenie generalnie efektywności pracy na linii zostały osiągnięte, przy, co jest bardzo ważne utrzymaniu ergonomii i nieobciążeniu pracowników nadmiernym tempem pracy.

Paweł Chmiela Dyrektor produkcji Flokk sp. Z o.o.

Efektywna intralogistyka w fabryce przyszłości w firmie Postęp

Głównym wyzwaniem było, istniejący układ pakowania dostosować do wymagań, brak miejsca a wymagania duże a to firma ASTOR spełniła.

Józef Borowiak Wiceprezes, Postęp Sp. Z o.o

Arctos Creme: trzy kroki do doskonałości – kompaktowa paletyzacja trzy w jednym

Paletyzacja z zastosowaniem chwytaka dostosowanego do paletyzacji trzech różnych produktów końcowych: kartonu klapowego, wiadra lub skrzynki spełnia oczekiwane wymagania, odciążając pracowników od ciężkiej fizycznej pracy.

Kopalnia Soli w Kłodawie: zrobotyzowana paletyzacja soli w zakładzie przeróbki soli spożywczej

Inwestujemy w nowoczesne technologie zakupiliśmy linie do produkcji worków 25kg jak również linię do produkcji paczek 1 kg każda z tych linii została zaopatrzona w odpowiednie roboty które tą sól układają na paletach. To rozwiązanie zwiększa nam efektywność i wydajność naszej pracy.

Waldemar Marciniak Prezes, Kopalnia soli Kłodawa S.A.

Valeo: Na drodze do doskonałości operacyjnej – inteligentna robotyka mobilna

„Robotyzacja intralogistyki w Zakładzie Wycieraczek znacząco poprawiła wydajność naszych procesów. Wprowadza również element innowacji i optymalizacji. Transferujemy tę wiedzę do innych zakładów Valeo w Europie i na świecie. ” – Dominik Wąsiel, Site Supply Chain Manager & Regional Supply Chain Enginner, Development Manager, Valeo, Zakład Produkcji Systemów Wycieraczek w Skawinie

Selected projects